At a glance

- Engineering plastics are a superior alternative to traditional materials, offering lightweight strength, chemical resistance, and long-lasting durability.

- Industries like food production, logistics, and chemical processing commonly use HDPE, UHMWPE, and polycarbonate sheets.

- Engineered plastics combine wear resistance with design flexibility and long-term cost savings.

- With online ordering, live stock tracking, and nationwide delivery, ePOL makes sourcing engineering plastics simple for Australian manufacturers.

The global manufacturing industry is evolving at an accelerated pace to address the rising demand, advancing technologies and the need for sophisticated lifestyles. In this growing environment, the materials used in manufacturing cannot be overlooked. This is where engineering plastics step in as a necessity in the expanding production market.

Engineering plastics, with their lightweight, high-strength, durable and chemically resistant properties, are replacing traditional materials like metal in a wide range of industries. From food processing to the automotive industry, they are becoming the go-to solution for manufacturers around the world.

Why is engineering plastic being celebrated across modern manufacturing? As a trusted supplier of engineering plastics in Australia, we will help you understand why engineering plastics are becoming the backbone of the manufacturing industry.

Key Advantages of Engineering Plastics in Manufacturing

Superior Strength-to-Weight Ratio

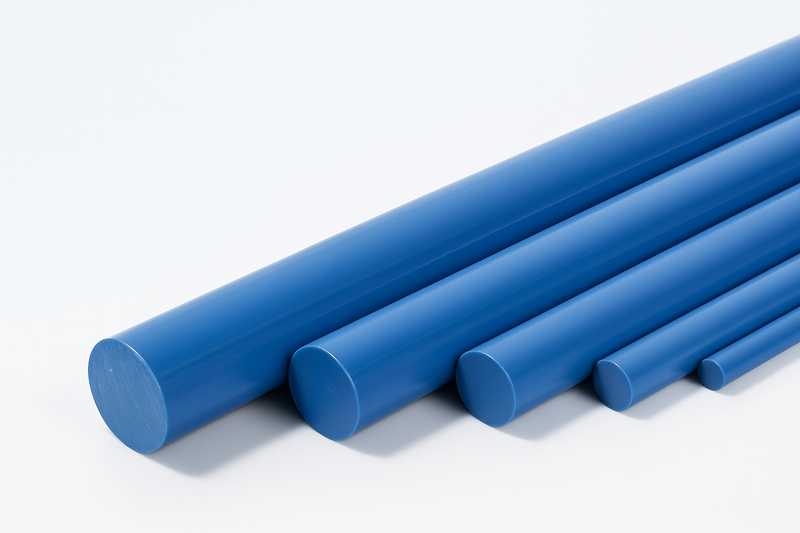

Engineering plastics are known for their great strength in contrast to their low weight. Metals, which have been used in manufacturing for a long time for their strength, are being replaced by engineering plastics. Options like Acetal (POM) and Cast Nylon offer excellent mechanical strength while being significantly lighter than metal alternatives.

These properties help them become an ideal option for weight-sensitive applications. This can range from automotive parts to machine housing uses.

For instance, Acetal Rods are commonly used for manufacturing high-tolerance parts like bearings and valve seats, the parts that need strength without the weight.

Read More: How Engineering Plastics are Transforming Manufacturing

Exceptional Chemical and Thermal Resistance

Another great advantage of engineering plastic, which has become one of the key reasons for its use in the production business, is its resistance to chemicals and heat. There is a limited number of materials that can be used in harsh environments where there is exposure to chemicals or high heat. Certain engineered plastics give the right solution in this scenario.

Options like the PTFE offer outstanding chemical resistance and can operate at elevated temperatures without degrading in quality and strength. This makes the product ideal for seals, gaskets, and linings in chemical processing plants.

For example, PTFE Sheets are widely used in chemical storage tanks and pipelines where aggressive substances would otherwise cause rapid material breakdown.

Read More: Understanding PTFE: Its Features, Advantages, and Emerging Applications

Low Friction and Excellent Wear Resistance

Friction is considered one of the major issues in production plants, causing components and machinery to wear down over time. Friction is more common in moving parts such as conveyer belts, so the plants should use a material with lower friction to reduce operational issues and downtime.

Engineering plastics like UHMWPE and PET offer low-friction surfaces and high abrasion resistance. This low friction extends the lifespan of components.

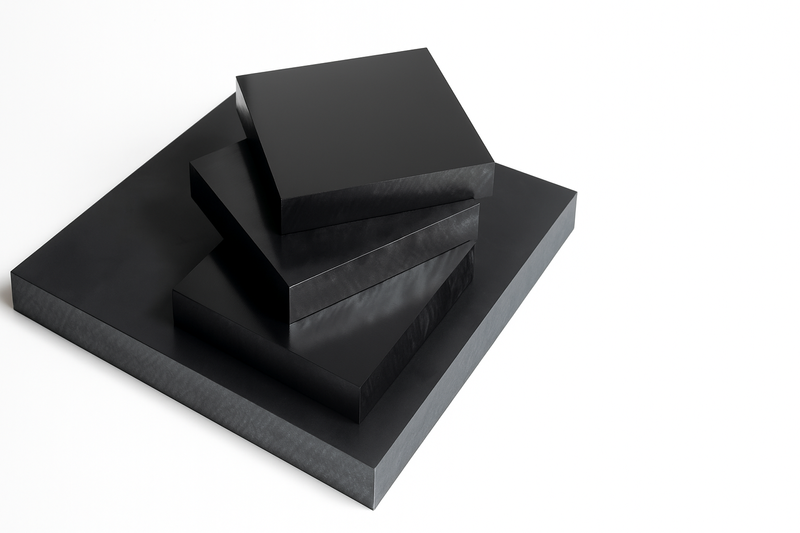

For example, UHMWPE Sheets are commonly used as chute liners and wear strips in bulk material handling systems, reducing material buildup and ensuring smooth flow.

Read More: Most Common Applications of UHMWPE

Design Flexibility and Machinability

Engineering plastics show better machining properties over metals since they enable manufacturers to design complex forms without production delays or increased expenses. Engineering plastics show excellent suitability for custom fabrication and prototyping because of their ability to adapt to new designs efficiently.

For example, Cast Nylon rods and sheets are used to produce custom bushings and rollers as well as structural parts for use within agricultural spheres and the transport industry alongside industrial settings.

Cost Efficiency Over Time

Premium options such as PEEK plastics have higher upfront costs but deliver long-lasting performance benefits, which results in better financial returns. These materials stay functional even when exposed to wear and chemicals. That said, they have two significant benefits: maintenance reductions with shorter downtime periods and a longer system lifespan.

HDPE Sheets provide cost-efficient solutions for cutting boards, tank linings, and mechanical covers while delivering durability and hygienic performance and omitting periodic maintenance expenses.

Read More: Understanding the Longevity of Different Engineering Plastics

Common Applications of Engineered Plastics in Modern Manufacturing

Engineered plastics’ innovation in multiple manufacturing sectors offers versatile solutions tailored to modern industry needs. First, food processing facilities benefit from HDPE and PET materials, which make excellent pieces for cutting boards, machine guards and conveyor parts because they resist moisture uptake and meet hygiene requirements as well as food safety standards.

Moreover, engineering plastics like UHMWPE have become the top choice in the transport and logistics sector because they minimise friction while enhancing flow efficiency and surface abrasion protection. In addition, Cast Nylon and Acetal excel are suitable for high-load mechanical moving parts because of their low-friction and self-lubricating properties.

PEEK and polycarbonate sheet materials deliver superior dielectric behavior and strength properties that make them ideal choices for medical equipment and electrical insulators. Likewise, PTFE and Polypropylene serve as essential materials in chemical processing environments because they provide unmatched resistance against aggressive chemicals.

Read More: Factors Influencing the Quality of Food-Grade Plastics in Manufacturing and Packaging Applications

All in all, high-performance materials have become essential for manufacturers because their operational requirements keep escalating with demands for efficiency and reduced downtime. Engineered plastics function as superior materials that provide enhanced performance alongside long-lasting solutions and better economic outcomes for varied industrial applications.

If you’re in need of the best engineering plastic suppliers, consider checking ePol. Through live stock tracking, price clarity, and a user-centric website, you can swiftly order engineering plastics online for your manufacturing business.

Benefit from ePOL’s nationwide delivery services and expertise today!